The UV LED market has huge development potential. How do LED manufacturers plan their layout?read count [209] release time:2020-03-13 19:48:00

In recent years, LED Technology continues to develop and industry competition continues to intensify. Major manufacturers are beginning to move to niche markets and look for new blue oceans. UV LED As a subdivided field with high gross profit, it has developed rapidly and attracted great attention from the industry. Domestic and foreign manufacturers have invested in it.

UV LED is widely used and has huge market development potential

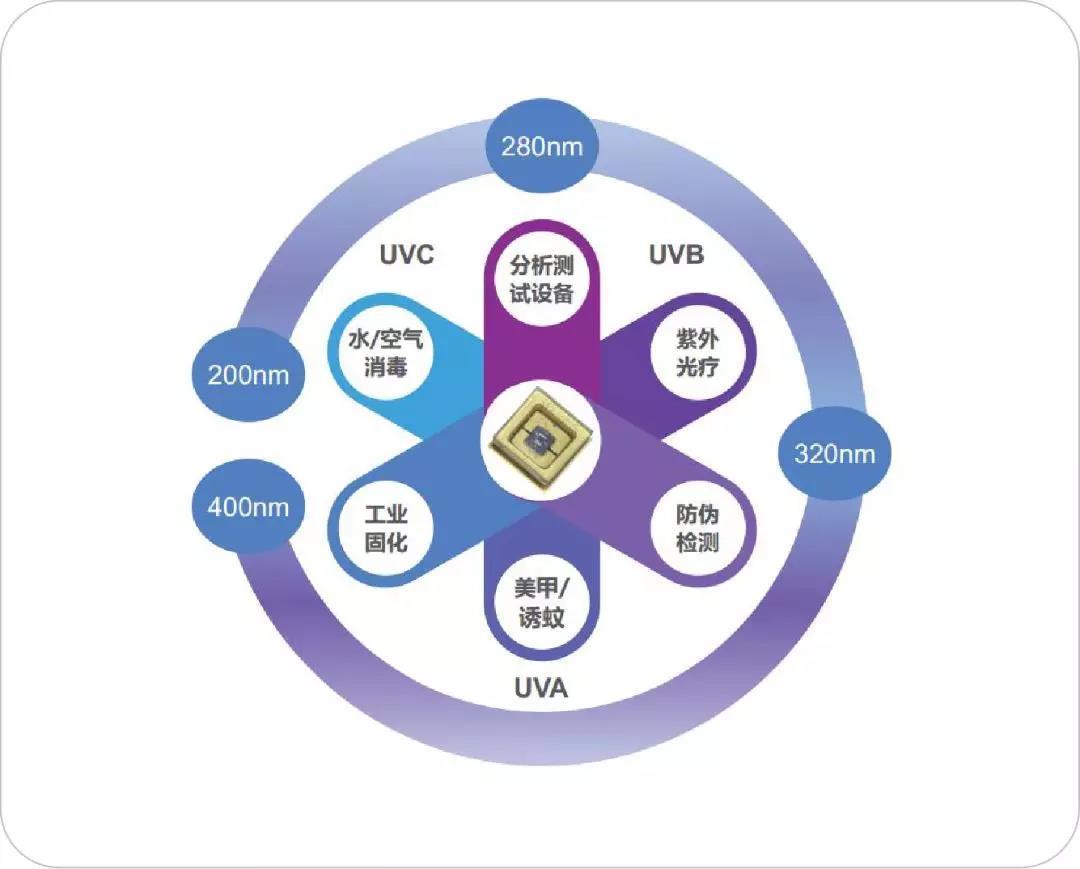

What is UV LED? UV LED refers to LEDs that emit light with a wavelength below 400nm. According to the wavelength, it can be further divided into UVA (320-400nm), UVB (280-320nm), and UVC (200-280nm).

Currently, the most widely used products are UVA products, which are mainly used in industrial fields such as glue curing, PCB exposure, and printing, as well as in civilian fields such as mosquito traps, manicures, anti-counterfeiting detection, and photocatalyst purification. The threshold for UVB and UVC is relatively high, especially UVC. UVB is mainly used for phototherapy, while UVC is mainly used for sterilization and disinfection.

According to the latest "2019 Deep UV LED Application Market Report - Sterilization, Purification and Water Treatment Market" released by TrendForce's LED Research Center (LEDinside), affected by the global recession, the revenue targets of UV LED manufacturers in 2018 failed to achieve explosive growth as expected, but still showed steady growth. Looking forward to the application market demand, in addition to the stable growth of the curing market, surface/air sterilization and purification, still water sterilization, and flowing water sterilization will be the main growth drivers in the future. It is estimated that the output value of the UV LED market will reach US$991 million in 2023.

With the entry into force of the Minamata Convention, primary mercury mines will be completely banned around 2030, and the production and supply of primary mercury will be impossible in the future. Since UV LED does not contain mercury, is environmentally friendly and safe, has the characteristics of fast start-up and high efficiency, its market development potential in the future is very huge.

The application of UV LED in emerging fields continues to expand

With the continuous development of UV LED technology, the application of UV LED in some emerging fields has been continuously expanded.

In addition, UV LEDs can be used for plant growth. In recent years, indoor and greenhouse cultivation have developed vigorously, which has solved the problem of lack of fresh vegetables in cold areas in winter. However, some of the indoor and greenhouse vegetables and fruits on the market have quality problems such as dark color and stale taste. There are many reasons for this, but insufficient light, especially the lack of ultraviolet component in normal light, may be the key factor. Research has found that adding a certain dose of UV radiation to indoor plantings such as greenhouses can affect plant growth and physiological activities, thereby improving plant quality.

At the same time, the application of UV LED in the field of phototherapy has gradually become popular. UVB can effectively treat various skin diseases such as psoriasis and vitiligo. Compared with the traditional NB UVB ultraviolet phototherapy device and excimer laser therapy device, UVB LED can be made more compact, easy to carry and use, and its advantages are more prominent.

Nowadays, as UV LED technology continues to mature and costs gradually decrease, UV LED will usher in new development opportunities.

Manufacturers actively deploy UV LED

In this regard, domestic and foreign manufacturers are rushing to deploy, especially high-threshold UVC LEDs. For example, LG Innotek, Seoul Viosys, DOWA, Qingdao Jason, Hongli Byingyi, Everlight Electronics, etc. are all actively developing UVC products.

UV LED series products, using high-reliability materials and excellent packaging technology, have lower thermal resistance, higher light output, and better air tightness. Taking the silicone 3535 series as an example, it combines nano-encapsulation technology to greatly reduce the thermal resistance of the device. The thermal resistance is more than 40% lower than conventional packaging products. The device has better heat dissipation and longer life. At the same time, a more reasonable primary lens package is designed, and the optical power is increased by more than 6% compared with conventional products.