How to choose air-cooled or water-cooled UV curing equipment?read count [537] release time:2021-08-02 08:36:00

UV curing equipment is through led The light-emitting chip converts electrical energy into ultraviolet light of specified wavelength. Although ultraviolet curing equipment emits a "cold light source" and does not produce infrared rays during the electro-optical conversion process, the conversion process will still generate a large amount of heat. Being in the process state for a long time will reduce the service life of the equipment, or even damage it seriously, so heat dissipation is required. Generally speaking, ultraviolet curing equipment has two heat dissipation methods.

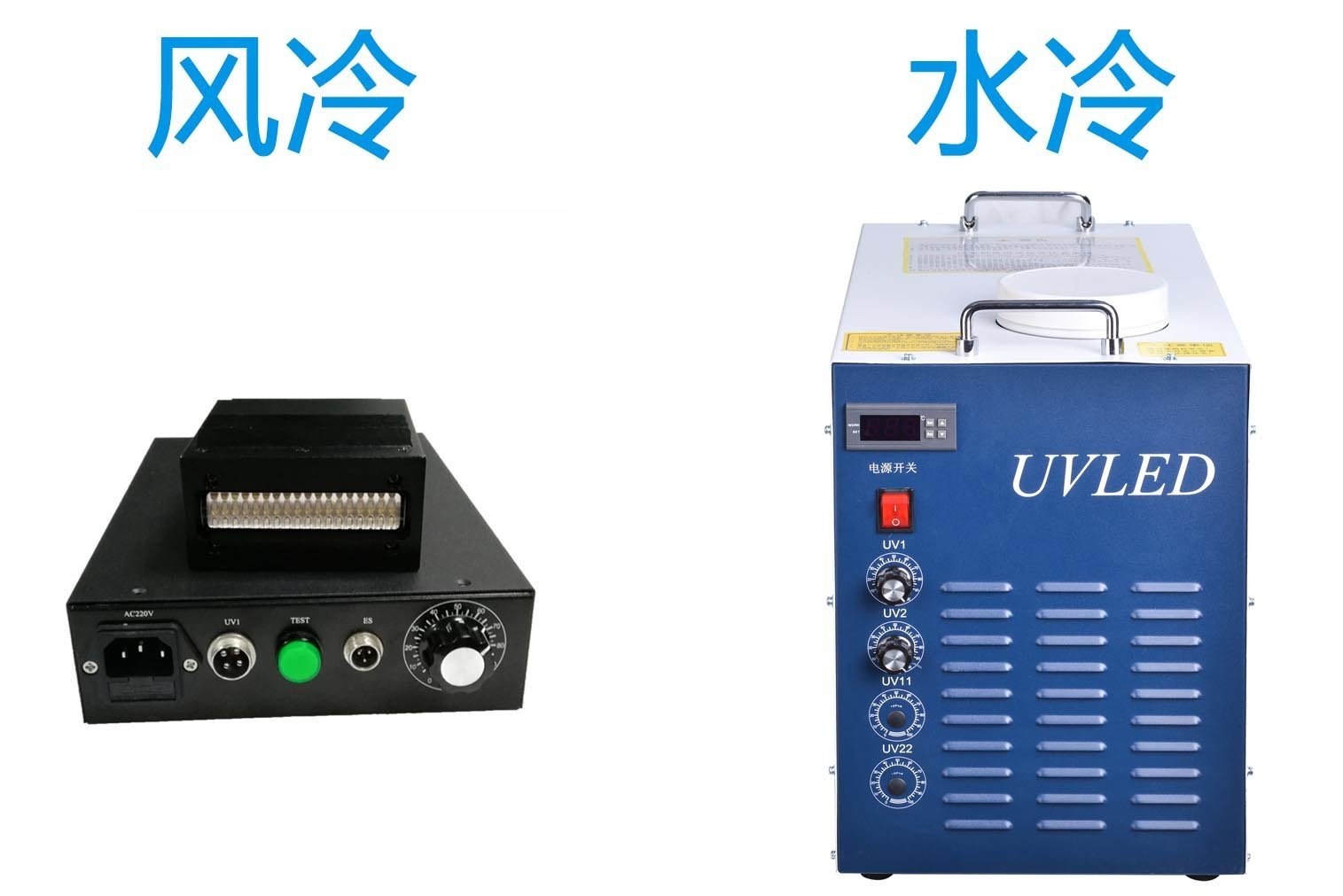

UV curing equipment heat dissipation method1: air-cooled

It refers to air-cooled ultraviolet curing equipment that can complete the job in a short time or the equipment power is not high. This type of equipment can reduce the temperature of the equipment to the normal operating range by dissipating heat through air cooling. The heat dissipation effect of air cooling is relatively not as good as that of water cooling, but the curing cost is lower and it takes up less space.

UV curing equipment heat dissipation method2:Water cooling

Compared with air cooling, water cooling has a much stronger heat dissipation capacity. Therefore, in some demanding workplaces that require high-intensity light, water cooling is used to dissipate heat. Water cooling can allow led The heat generated on the chip flows directionally with the coolant. At the same time, the whole machine has good sealing performance, low noise, dustproof and environmental protection. It also has real-time temperature monitoring function, which is convenient and flexible. But precisely because it is water-cooled, the curing cost is much higher and the floor space is large. Moreover, water-cooled ultraviolet curing equipment has relatively high environmental requirements. When the temperature is low, pay attention to the freezing of the coolant. During use, the water flow passes through LED When the chip takes away heat energy, it will also produce electrochemical corrosion. Corrosion inhibitors need to be added for long-term use. In the cooling circulation system, avoid letting solid particles or fine dust enter to prevent the impact UVLED Normal use of curing equipment!

The two heat dissipation methods of UV curing equipment are air cooling and water cooling. Different heat dissipation methods are suitable for different scenarios. How to choose depends on the actual usage scenario.