Introduction to UV screen printingread count [690] release time:2022-04-28 17:22:00

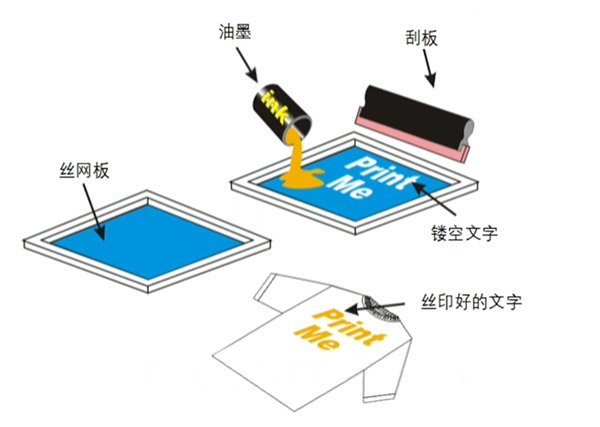

Screen printing refers to using a silk screen as a base plate and using a photosensitive platemaking method to create a screen printing plate with graphics and text. Screen printing consists of five major elements, screen printing plate, scraper, ink, printing table and substrate. Screen printing is one of the main forms of printing technology currently.

Screen printing example

The history of screen printing

Screen printing first originated in China and has a history of more than 2,000 years. It was introduced to Europe in the 18th century, but its popularity as a fabric printing method was slow due to the high cost of screen printing at the time. By the early 20th century, printers had developed light-sensitive emulsions, which made it easier for craftsmen to create complex stencil designs.

Nowadays, in the era of modern electronics and laser printing, screen printing is an ancient craft. This printing process technology with very distinctive printing characteristics and imaging processes, precisely because of its flexibility and wide adaptability, makes many printed matter use screen printing instead of offset printing in order to express creative design concepts more vividly.

Screen printing display

Screen printing ink

There are three types of screen printing inks classified according to drying methods: volatile drying ink, oxidative drying ink, and ultraviolet curing ink.

Volatile drying ink

The solvent in the ink diffuses in the atmosphere due to vapor pressure, forms a liquid film on the surface of the ink film, and then evaporates through the liquid film. In this drying process, the internal drying is generally slow, and sometimes it is necessary to blow air to speed up the drying process.

Volatile inks are easy to use and generally dry quickly, so they are widely used.

Oxidation drying ink

The ink contains polymers with smaller molecular weights, which are oxidized in the air and form a polymer film through chemical reactions of heat, light or reactive substances. After this kind of ink is printed on the surface of the substrate, it generally needs to be heated to promote hardening.

UV curable ink

UV ink can produce a photochemical reaction and can be completely cured within a few seconds. It is increasingly used in plastic printing. The main components of the ink are photopolymerizable resin, initiator, colorants and additives. In principle, organic solvents are not used.

UVLED screen printing

Compared with the use of volatile drying inks and oxidative drying inks, UVLED screen printing inks have the following advantages:

Fast curing speed, UV equipment is small in size and has high production efficiency

Especially suitable for multi-color, fully automatic flow operations. In the past, solvent-based ink drying required a long drying line, and some monochrome prints even required a drying device of about 10 meters. If UV ink printing is used, only one UV light source is needed to solve the problem. It saves the cost of purchasing equipment, saves space, and greatly improves production efficiency.

The ink will not block the screen and has stable concentration, suitable for high quality

Solvent is an important component of screen printing ink. In different regions, temperatures and humidity, the performance of the ink is also different. Some people say that 90% of the problems in the screen printing process are related to solvents. UV ink does not contain volatile substances, the viscosity of the ink changes very little, and it is easy to operate. It solves these problems well and greatly improves the printing quality. In addition, because the ink solidifies quickly, it shortens the residence time of the printed matter during the drying process and reduces the possibility of being contaminated by dust.

Contains no volatile solvents and has no negative impact on the human body or the environment

Currently, in terms of output and variety of screen printing inks, volatile drying solvent inks dominate. Because of its slow drying time, 60% of the solvent evaporates during the drying process, causing environmental pollution. The pursuit of inks with less pollution, faster drying and less energy consumption has become a common goal for people in the printing industry.

Thick ink layer, wide range of printing materials, simple and flexible operation

The solid content of general solvent ink is about 40%, while the solid content of UV ink after curing is close to 100%, which is 2 to 5 times that of general ink. If you use thick film screen printing UV ink, the effect will be better.

Shenzhen Yongcheng Optoelectronics Co., Ltd. is a national high-tech enterprise engaged in the development, manufacturing, sales and service of UV LED curing equipment. In the current screen printing industry, due to production, environmental protection, energy saving and other reasons, many companies are gradually using UVLED curing screen printing machines. As a leading domestic UVLED light source supplier, Yongcheng has provided many well-known domestic screen printing machine manufacturers with UVLED curing lamps that match their products for more than ten years. The quality of its products has been recognized by customers.