Dispensing process and UVLED curing of TWS earphonesread count [644] release time:2022-08-09 14:33:00

2014-2018 is the period of wireless intelligence for headphones. Earphones have finally gotten rid of the shackles of cumbersome earphone cables, but because of their wireless design, they also have many requirements for their dispensing process. Because UVLED cured glue has the characteristics of quick drying, wide applicability, and small shrinkage, it has also become one of the most commonly used glues for TWS headphones.

Wireless headsets need to install more functional modules and as large a battery as possible in an inherently small and limited space. This requires the internal components of wireless headsets to be designed very precisely and the component structure to be as compact as possible. And the anti-fall and anti-vibration requirements for headphones are also extremely strict. UVLED curing glue can be used for bonding and fixing wireless earphone shells, dust screens, voice coils, diaphragms, circuit boards, components, etc. It can also improve the vibration resistance of small components and the waterproof and dustproof capabilities of shells, PCB boards, dust screens, charging ports, soldering joints and other structures.

Unlike other dispensing products such as mobile phones, TWS earphones are small and round in appearance. For example, the outer diameter of the bottom part of common boxed Bluetooth earphones is about 5~7mm, while the inner diameter is usually less than 4mm. The internal components are precise and diverse, the structure is complex, and the dispensing path is also complicated. For example, gap filling requires a 0.25mm wide arc-shaped gap behind the top of a slope to evenly fill with glue, and the interior is fully filled and no glue overflow is allowed.

In addition, the consistency of the glue amount will also directly affect the quality of the product. TWS earphones have very high requirements for glue amount control, such as gap filling. 1.68mg of glue is accurately filled in each uniform gap, and the glue weight accuracy is ±3%. In order to meet such a standard, the process of this link places extremely high requirements on the accuracy, speed and stability of the dispensing machine. It is difficult to achieve such an effect with manual dispensing, so automated equipment must be used for dispensing.

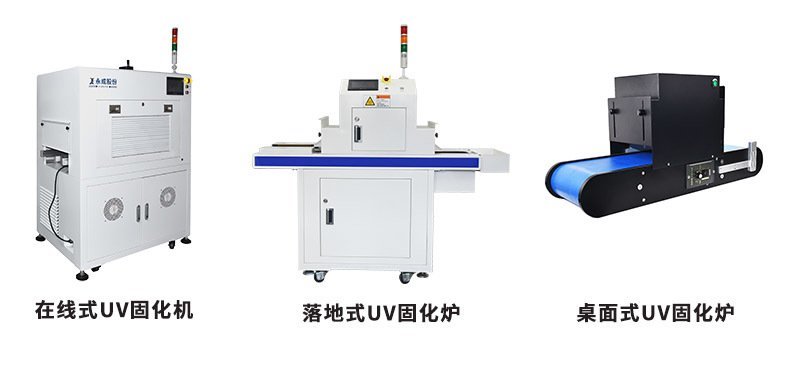

Shenzhen Yongcheng Optoelectronics Co., Ltd. has been working in the field of automation equipment for many years and has launched various models of online Automated equipment such as UV curing machines, floor-standing UV curing ovens, and desktop UV curing ovens can be adapted to different automated dispensing and curing production lines to improve the production efficiency and product quality of TWS headsets.