Introduction to UVLED Flexo Printingread count [968] release time:2022-05-14 15:38:00

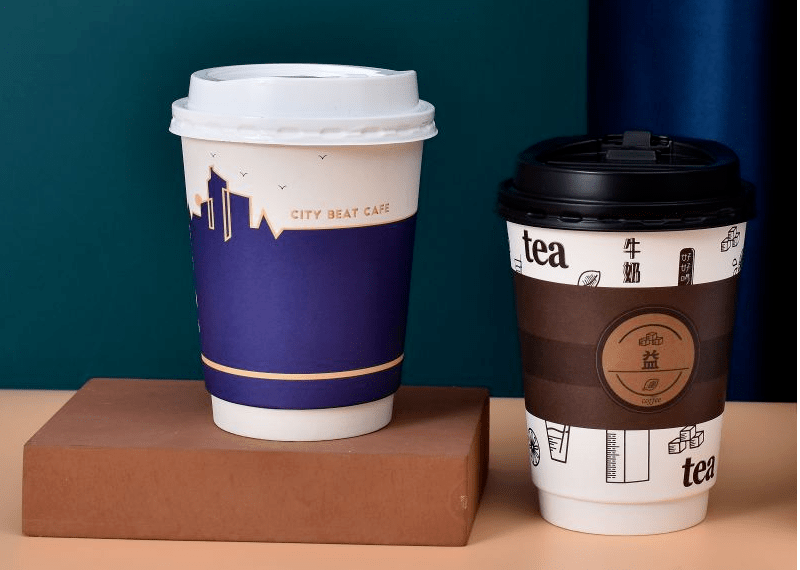

UVLED flexo printing is a printing method that uses elastic letterpress plates. It has a series of advantages such as good printing quality, adaptability to a wide range of printing materials, high production efficiency, convenient operation and maintenance, low investment, high profits, and compliance with environmental protection requirements, making flexo printing the printing solution of choice for various packaging products.

Pictures from the Internet

Flexo printing development

Flexographic printing is a relief printing method, originally called flexographic printing. It originated in the United States in the early 1920s. It failed to develop because the aniline dye ink used was toxic.

After that, ink manufacturers began to use colorants that were acceptable to everyone, and it was renamed flexographic printing (Flexographic Process) at the 14th American Packaging Symposium in 1952.

In the 1970s, with the advancement of the materials industry, especially the advent of polymer resin plates and cermet anilox rollers, the development of flexographic printing made a qualitative leap.

Pictures from the Internet

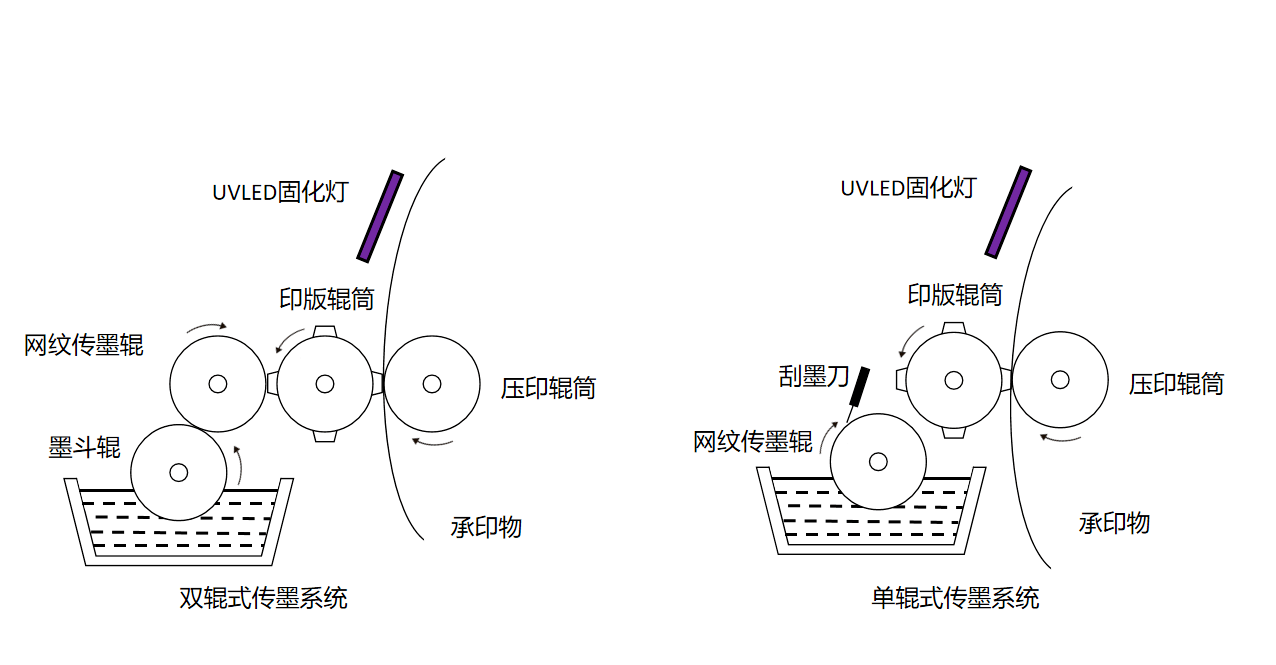

The principle of UVLED flexo printing

When printing, the ink transfer roller (rubber roller) in the ink tank first transfers the stained ink to the ink transfer roller (anilox metal roller), and then the ink transfer roller removes the excess ink on the surface of the anilox ink transfer roller, and then the ink transfer roller applies the ink on the surface of the printing plate cylinder evenly and stably.; When the printing material (such as plastic film) passes between the printing plate cylinder and the impression cylinder, the graphics and text on the printing plate are transferred to the printing material under pressure, and then the ink is dried and solidified by the UVLED curing lamp to obtain clear graphics and text.

How does a UVLED curing lamp dry and cure UV ink? Because UVLED curing lamps can emit ultraviolet light of a specific band, UV ink can absorb these ultraviolet lights to produce a cross-linking reaction, allowing the ink to complete curing from a liquid state in just a few seconds, greatly increasing production efficiency.

Shenzhen Yongcheng Optoelectronics Co., Ltd. has been focusing on the production and research and development of UVLED curing equipment for 13 years. It has dozens of patented inventions and is a leading enterprise in the UVLED printing industry. It has matching UVLED curing lamps for the assembly and installation of printing equipment. It also supports non-standard customized UVLED curing equipment.