The development history of inkjet printing and the development of UV LED inkjet printersread count [872] release time:2022-04-02 15:16:00

Development history

Application of continuous inkjet technology

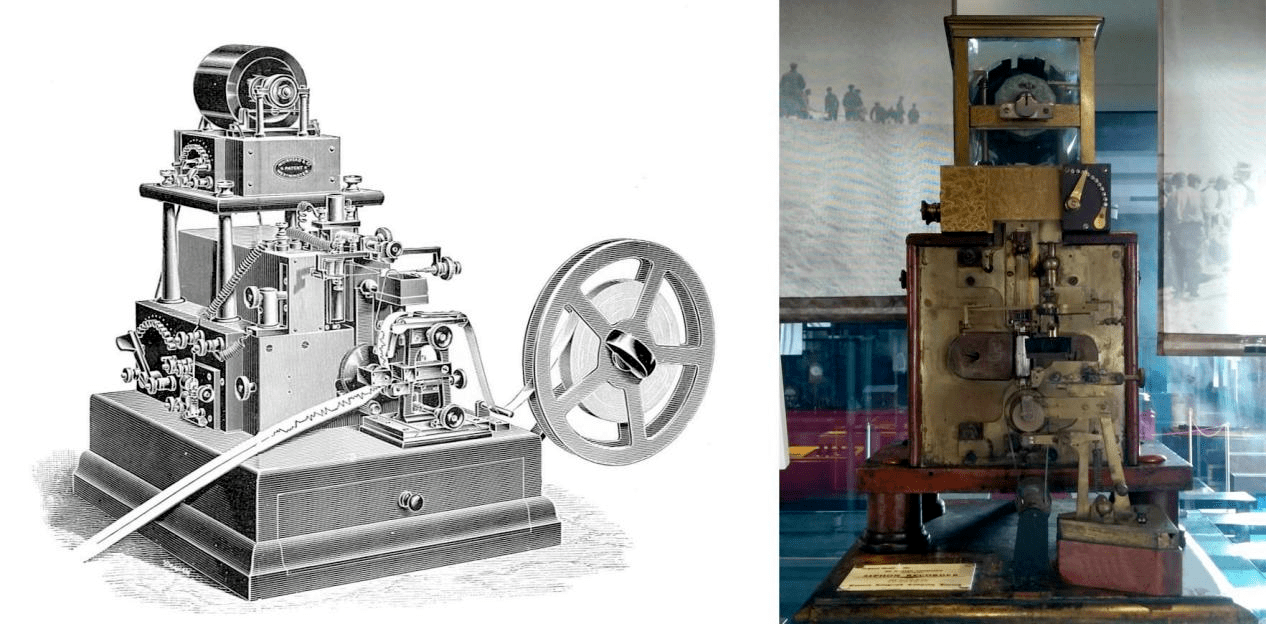

The development of inkjet printing has a long history. Broadly speaking, as early as 1867, the predecessor of the inkjet printer, the continuous inkjet telegraph recorder, had been invented.

Early continuous inkjet telegraph recorder, source: Wikipedia

Until the 1960s, with the study of basic theories such as the formation of ink droplets and their movement in electric fields, the theory of continuous inkjet printing gradually took shape and began to enter the application stage. In the 1970s, with the development of computer technology, continuous inkjet print heads for inkjet printers appeared.

drop-on-demand inkjet technology

However, the application scenarios of continuous inkjet are limited. It is impossible for a small consumer printer to keep ink leaking out. Therefore, inkjet on demand is necessary. For drop-on-demand inkjet, the technical problem of how to control the ejection of ink droplets must be solved.

In order to make the ink droplets spray out accurately, there are many methods. But in the end everyone found these two ideas to be the most reliable:

The first idea is to put something else, such as gas, into the ink tank from above, so that the gas can push out the ink droplets below.

The second idea is to squeeze the ink tank from above to make the space of the ink tank smaller, so that the ink droplets can be ejected from the bottom of the ink tank. This is just like pushing a needle, very easy to understand.

These two main technical routes are our today’s thermal foaming technology and micro-piezoelectric technology.

The picture on the left shows micro-piezoelectric and the picture on the right shows thermal foaming. Source: wikipedia

Development and application of thermal bubble inkjet technology

In the 1980s, the principle of thermal bubble printing was discovered. Subsequently, thermal bubble inkjet printing technology was perfected and thermal bubble inkjet print heads appeared. Compared with continuous inkjet printheads, thermal bubble inkjet printheads have higher working efficiency and printing accuracy. At the same time, the ink supply method is simple and does not require additional pressurization devices and terminal recovery devices. Therefore, thermal bubble inkjet printheads began to gradually replace continuous inkjet printheads.

In the 1990s, thermal bubble inkjet print heads began to be used in digital printing equipment for outdoor advertising.

Development and application of piezoelectric inkjet technology

In the 1990s, with the further development of piezoelectric inkjet printing technology, piezoelectric inkjet print heads began to gradually enter the stage of substantial application. Compared with thermal bubble inkjet printheads, piezoelectric inkjet printheads have stronger control over ink droplets. The ink droplets formed during the ejection process are smaller in size, have faster ejection speeds, and have higher ejection frequency. At the same time, the piezoelectric inkjet print head does not need to be heated during the ejection process, and the ink will not undergo chemical reactions due to high temperatures, which greatly reduces the equipment's requirements for ink quality. In addition, piezoelectric inkjet print heads are also suitable for printing media that are not charged and are not subject to bubbles caused by high-temperature vaporization. ; However, compared with thermal bubble inkjet printheads, piezoelectric inkjet printheads are more expensive. Therefore, piezoelectric inkjet print heads are only gradually used in the field of mid-to-high-end outdoor advertising inkjet printing that requires higher printing quality.

Development of UV LED inkjet printer

Mercury lamp application stage:

Before 2008, there were already UV mercury lamp inkjet printers on the market. At this stage, there were very few domestic UV inkjet printer manufacturers. Due to the immaturity of the technology and the relatively high price, the price of the UV ink used was higher than that of solvent-based ink. In addition, the cost of UV lamps was also added. When most users consider these issues, they still choose solvent-based inkjet printers.

UV LED emerges:

At the Drupa 2008 international printing exhibition held in Germany in May 2008, Japan's Ryobi, Panasonic and Nichia companies launched UV-LED inkjet printing equipment, which caused a sensation in the entire printing industry. The emergence of UVLED has solved many shortcomings of curing mercury lamps.

UV LED completely replaces mercury lamps:

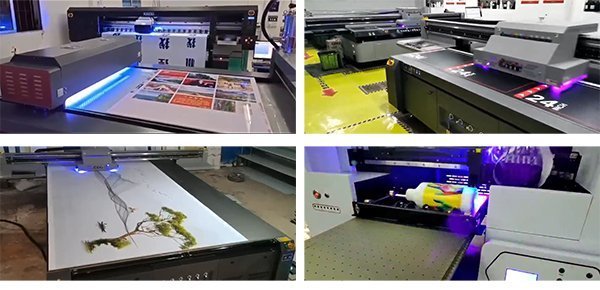

UVLED printing equipment

exist From 2013 to the 2019 Shanghai International Advertising Exhibition, more than a dozen domestic inkjet printing equipment manufacturers exhibited UV-LED inkjet printing equipment. At the 2018 and 2019 Shanghai International Advertising Exhibition, all UV inkjet printing equipment and UV inkjet inks were UV-LED. Inkjet printing equipment and UV-LED inkjet printing ink, there are no UV inkjet printing equipment and UV inkjet printing ink exhibitors. In just ten years, in the inkjet printing industry, UV-LED curing has completely replaced mercury lamp UV curing, fully demonstrating the superiority and advancement of UV-LED technology. There are more than 500 domestic UV printing equipment manufacturers. Shenzhen Yongcheng Optoelectronics Co., Ltd. was established in 2009 and is committed to the research, development and production of UVLED curing light sources. It is one of the earliest UVLED R&D and production companies to enter the field of inkjet printing curing. It has made great contributions to the development of curing light sources for inkjet printers. In 2 In 2016, Yongcheng Optoelectronics Co., Ltd. became a leading company in the field of inkjet printing and curing and expanded its business to overseas markets. It currently accounts for more than 60% of the domestic inkjet printing market and has been recognized by the China Product Quality Management Center and the China Brand Development Promotion Federation.