Introduction to UV offset printingread count [669] release time:2022-05-09 17:23:00

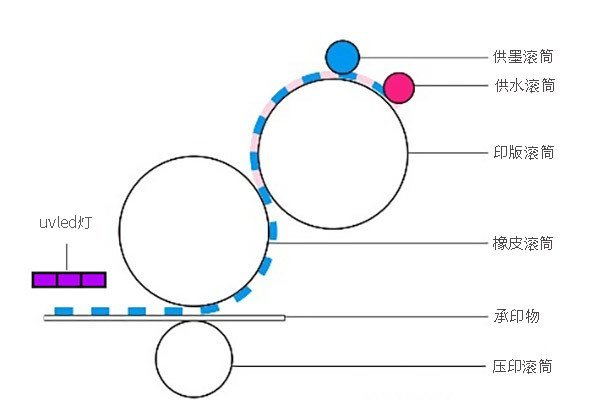

Offset printing, also known as offset printing, is the most widely used printing method in the printing field. The graphic and non-graphic parts of offset printing are basically on the same plane. The graphic part is hydrophilic and hydrophobic, and the non-graphic part is hydrophilic and oleophobic. Most offset printing uses the principle of oil-water immiscibility to complete printing. The principle is to press the ink onto the printed paper through rubber glue through a roller, thereby producing different prints. With the continuous development of the offset printing industry, more and more manufacturers are beginning to use UV ink.

Used in the offset printing process UV Ink has the following specific advantages:

①The printing quality is excellent. UV Offset printing ink is cured and dried immediately after printing. The ink does not penetrate into the printing material, so the colors are more vivid, which greatly improves the color saturation of the printed matter. The ink spread is small, resulting in small dot enlargement, higher definition, and good tonal reproducibility of the printed matter, which is very suitable for printing fine products.

②Green and environmentally friendly. UV The ink contains almost no volatile organic compounds during the printing process ( VOCs ) emissions, solving the problem of environmental pollution during the ink drying process. in addition, UVLED Curing equipment enables UV The ink solidifies quickly at low temperature, and its energy consumption is much lower than the energy consumed by ordinary ink printing through hot air or infrared drying, which can save a lot of energy.

③Improved printing process. UV Ink Sutra UV It is cured when irradiated by a light source. It will not form a skin in the ink tank before irradiation, nor will it dry out on the printing machine or printing plate. Therefore, there is no need to clean the ink roller and printing plate when the offset printing machine is shut down, which solves the worries about the shutdown of the offset printing machine, reduces the waste of ink, and saves cleaning time.

④This makes offset printing suitable for a variety of printing materials and broadens the application scope of offset printing. use UV Ink allows offset printing to expand from the main printing paper to composite paper materials, metal, plastic and other printing materials. Common problems with ordinary inks on these materials include slow drying, low adhesion, and poor friction resistance. and UV The ink is UV The cross-linking polymerization reaction occurs under light and dries and solidifies quickly, and cross-links to form a network structure, which greatly improves the physical properties of the ink layer surface and fundamentally solves the problems of slow drying, poor adhesion and friction resistance.

⑤Expanded the application of offset printing in special fields. along with UV With the application of ink, many manufacturers use it to print some special products, such as grating three-dimensional printing, so that three-dimensional printing can be produced in large quantities, and the quality of the products has been further improved.

This picture comes from the Internet

Shenzhen Yongcheng Optoelectronics Co., Ltd., in UVLED He has more than ten years of R&D and production experience in curing equipment. When it comes to installing light curing equipment for offset printing machines, Heidelberg and KBA ( KBA ), Manroland, Komori, Mitsubishi, Akiyama and other brands of offset printing presses all have suitable models. UVLED lamp.