UV irradiation cross-linking and silane cross-linking of cablesread count [752] release time:2022-11-08 16:01:00

Ultraviolet irradiation cross-linking is another new cross-linking technology developed in recent years. It is a technological innovation independently developed by my country, an international initiative, and with independent intellectual property rights. It has opened up a new way for cross-linked cable production technology. UV irradiation cross-linking wire and cable is the latest technical field that applies the technology of "UV irradiation processing" to the modification of polymer materials. UV irradiation processing is to irradiate polymer materials under normal pressure when the polymer materials are extruded into a molten state. It does not damage the materials, is efficient and energy-saving, and the light can penetrate deep into the interior of the polymer without bringing any residual poison or waste. The control method is simple and suitable for industrialization and large-scale production.

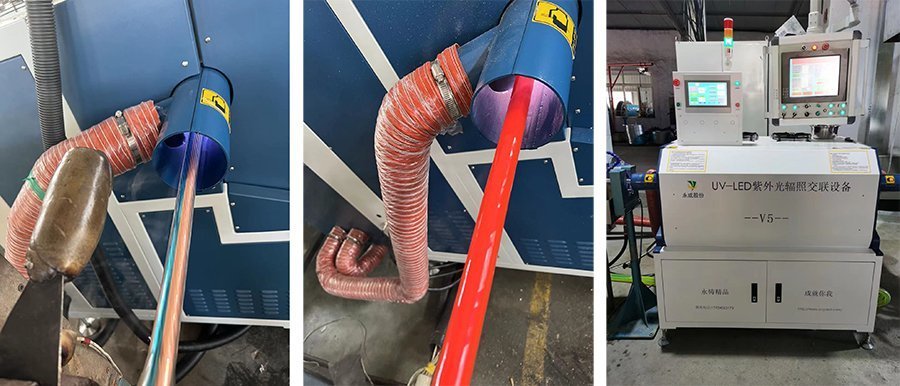

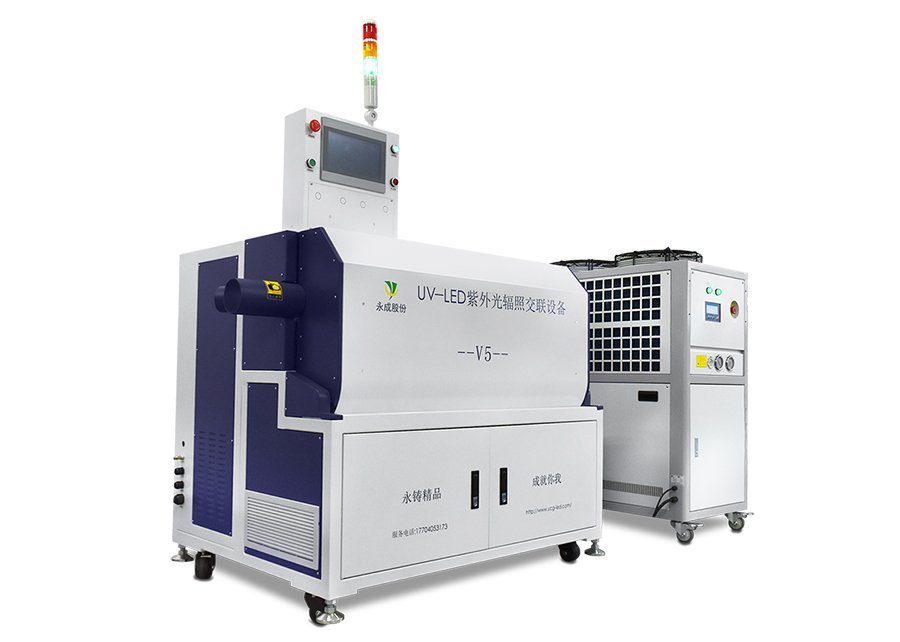

UV irradiation cross-linking machine usage site

The most commonly used silane cross-linking methods are one-step method, two-step method and copolymerization method. This method has the following disadvantages during production:

1. Silane polyethylene is sensitive to water and requires high storage conditions. Generally, after the base material is opened, it must be used up within 5 hours.;

2. The storage period of grafted polyethylene and catalyst masterbatch mixture is generally not more than 3 hours. Otherwise, it is easy to absorb water and cause early cross-linking.;

3. Impurities are easily introduced during the production process;

4. The screw and machine head need to be cleaned after the machine is stopped. The work intensity of workers is high and the waste of material is large.;

5. The one-step method requires the use of a special extruder to extrude the mixture of a specific formula at one time, which brings limitations to the promotion and application of the process.

Advantages of UV irradiation cross-linking

1. UV cable materials are not easy to absorb moisture and do not require secondary drying or mixing. They can be extruded with an ordinary extruder or with a special extruder. The extrusion process is easy to control and will not cause early cross-linking. There is no need to clean the screw after shutdown. The insulation surface is flat and smooth after extrusion.

2. UV cross-linked polyethylene insulated cable materials are packed in double-layer packaging bags. Among them, the inner packaging bag is a black plastic bag, and the outer packaging bag is a composite paper bag. The used cable material is put into the packaging bag and stored in a dry and light-proof environment. It can be put into the extruder the next time it is used.

3. High production efficiency

The production speed of UV cross-linking and silane cross-linking extrusion is the same. After extrusion, silane cross-linked cable insulation generally needs to be placed in a silane cross-linking tank for cross-linking. About 4 to 6 hours. After taking it out, in order to ensure that the moisture on the insulation surface evaporates, it should be stored indoors for at least 12 hours before it can be transferred to the next production process. After extrusion, UV cross-linked insulation can be cross-linked within a few seconds after being irradiated by a light source. After extrusion, it can be directly transferred to the next process for production, which can significantly improve production efficiency.

Yongcheng has rich experience in UV irradiation of wires and cables. Currently, it has It has 1 invention patent, 2 utility model patents and an appearance patent. It is also a member of the Guangdong Wire and Cable Industry Association and a member of the China Radiation Curing Association.