Electronic connector dispensing and UVLED curingread count [558] release time:2022-08-27 10:39:00

There are many types of electronic connectors. They are usually a connecting device used to connect two active devices and transmit current or signals. They are an indispensable part of electronic equipment. Common electronic connectors include data cables, audio cables, monitor cables, etc.

electronic connector

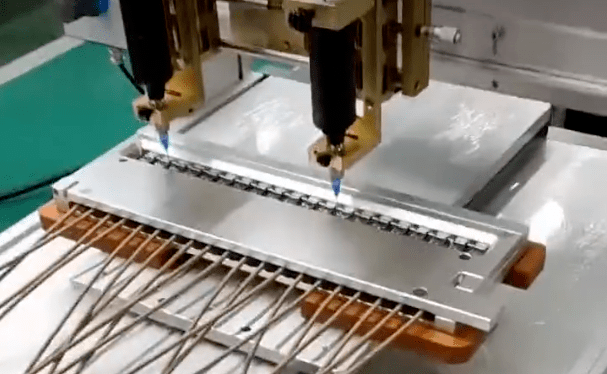

The function of glue dispensing is to auxiliary fixation of wires and connecting parts. After glue dispensing processing, the connection has the characteristics of enhanced stability, waterproof and moisture-proof, high pressure resistance, high and low temperature resistance, corrosion resistance, etc. It improves the impact resistance and seismic resistance and extends the service life of the connector.

Electronic connector dispensing

With the sophistication of connectors, the requirements for dispensing accuracy are getting higher and higher. The use of connector dispensing processing technology can precisely and accurately apply glue dots to small contact surfaces, reducing the waste of glue materials. To a certain extent, it can simplify the production and manufacturing process and shorten the processing time.

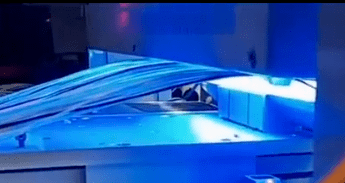

Electronic connector UV glue curing

There are many types of glue for electronic connector dispensing. The common curing types include AB glue curing and UV curing. AB glue takes a long time to cure. AB glue with fast curing time only reaches initial curing in 5 minutes, and complete curing takes 8-12 hours. It will also be affected by temperature. The lower the temperature, the slower the curing speed. The long curing time makes AB glue unable to be produced with automated production lines and cannot improve production efficiency. UVLED glue needs to be used with a UVLED curing lamp. Under the irradiation of the UVLED curing lamp, the UVLED glue can be cured in seconds. The UVLED glue can be completely cured in a few seconds, and then the next step can be carried out, which effectively improves production efficiency.

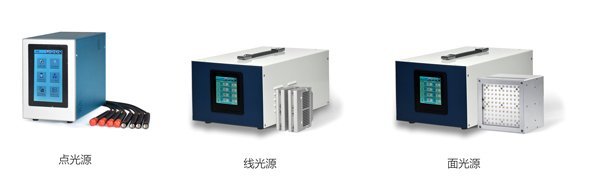

The popularity of automated production lines has led many manufacturers to use automated equipment for production. Electronic connectors can be dispensed through automated dispensing equipment. After the dispensing is completed, they can be cured through UVLED curing lamps. After curing is completed in a few seconds, the next step can be entered. . Shenzhen Yongcheng has rich experience in the development and production of UVLED glue curing equipment for electronic connectors. Currently, it has a variety of UVLED curing equipment. Point light sources can be used with automated dispensing machines for precision dispensing. Line light sources and surface light sources can be used with production lines for batch dispensing. The equipment can not only be used alone, but can also be equipped with assembly lines for linked production. In addition to existing models of UVLED curing equipment, it can also be customized according to the actual needs of customers to truly solve customer needs.